2025 Textile Electrospinning Nanofibers Market Report: Growth Drivers, Technology Innovations, and Strategic Insights for the Next 5 Years

- Executive Summary & Market Overview

- Key Technology Trends in Electrospinning Nanofibers

- Competitive Landscape and Leading Players

- Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

- Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Future Outlook: Emerging Applications and Investment Opportunities

- Challenges, Risks, and Strategic Opportunities

- Sources & References

Executive Summary & Market Overview

The global textile electrospinning nanofibers market is poised for significant growth in 2025, driven by increasing demand for advanced materials in filtration, medical textiles, protective clothing, and smart textiles. Electrospinning is a versatile technique that produces nanofibers with diameters ranging from tens to hundreds of nanometers, offering high surface area-to-volume ratios, tunable porosity, and superior mechanical properties compared to conventional fibers. These characteristics make electrospun nanofibers highly attractive for applications requiring enhanced performance, such as air and liquid filtration, wound dressings, drug delivery systems, and functional apparel.

According to Grand View Research, the global nanofibers market size was valued at USD 1.2 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of over 18% from 2024 to 2030. The textile segment is a key contributor to this growth, with electrospinning emerging as the dominant production method due to its scalability and ability to process a wide range of polymers, including biopolymers and composites. The adoption of electrospun nanofibers in the textile industry is further accelerated by ongoing innovations in process control, material functionalization, and integration with traditional textile manufacturing techniques.

Regionally, Asia-Pacific leads the market, fueled by robust textile manufacturing infrastructure in countries such as China, India, and South Korea. North America and Europe are also significant markets, driven by strong R&D investments and the presence of leading nanotechnology companies and research institutions. Notable industry players include Elmarco, Nanofiberlabs, and FibeRio Technology Corporation, all of which are actively developing commercial-scale electrospinning solutions for textile applications.

- Key Market Drivers: Rising demand for high-performance filtration media, growth in healthcare and hygiene sectors, and increasing focus on sustainable and functional textiles.

- Challenges: High production costs, scalability issues, and regulatory hurdles related to nanomaterials in consumer products.

- Opportunities: Advancements in green electrospinning processes, development of smart and responsive textiles, and expanding applications in energy storage and environmental remediation.

In summary, the textile electrospinning nanofibers market in 2025 is characterized by rapid technological advancements, expanding end-use applications, and a dynamic competitive landscape, positioning it as a critical segment within the broader nanomaterials industry.

Key Technology Trends in Electrospinning Nanofibers

Textile electrospinning nanofibers are at the forefront of innovation in the textile industry, driven by their unique properties such as high surface area-to-volume ratio, tunable porosity, and the ability to incorporate functional additives. In 2025, several key technology trends are shaping the development and commercialization of electrospun nanofibers for textile applications.

- Scalable Production Techniques: Traditional electrospinning methods have faced challenges in scaling up for industrial textile manufacturing. Recent advancements include multi-jet and needleless electrospinning systems, which significantly increase throughput and fiber uniformity. Companies are investing in roll-to-roll and free-surface electrospinning technologies to enable continuous, large-scale production of nanofiber mats suitable for integration into fabrics (Freudenberg Group).

- Functionalization and Smart Textiles: The integration of functional materials—such as antimicrobial agents, phase-change materials, and conductive nanoparticles—into electrospun nanofibers is enabling the creation of smart textiles. These textiles offer enhanced properties like self-cleaning, temperature regulation, and real-time health monitoring, catering to the growing demand in sportswear, medical, and military sectors (TechnicalTextile.net).

- Sustainability and Biodegradable Materials: Environmental concerns are driving the adoption of biodegradable and bio-based polymers in electrospinning. Polymers such as polylactic acid (PLA) and polycaprolactone (PCL) are being increasingly used to produce eco-friendly nanofiber textiles, aligning with global sustainability goals and consumer preferences for green products (MarketsandMarkets).

- Advanced Post-Processing and Hybridization: Post-spinning treatments, including plasma modification and surface grafting, are being employed to further enhance the performance of nanofiber textiles. Additionally, hybridization with other fiber types (e.g., microfibers or natural fibers) is expanding the range of achievable properties, such as improved mechanical strength and moisture management (Elsevier).

- Integration with Digital Manufacturing: The convergence of electrospinning with digital textile manufacturing techniques, such as 3D printing and automated patterning, is enabling the production of highly customized and complex textile structures. This trend supports the shift toward on-demand and personalized textile products (Textile World).

These technology trends are expected to accelerate the adoption of electrospun nanofibers in mainstream textile applications, driving innovation and opening new market opportunities in 2025 and beyond.

Competitive Landscape and Leading Players

The competitive landscape of the textile electrospinning nanofibers market in 2025 is characterized by a mix of established material science companies, innovative startups, and academic spin-offs, all vying for leadership in a rapidly evolving sector. The market is driven by increasing demand for advanced textiles in filtration, medical, and protective apparel applications, with players differentiating themselves through proprietary electrospinning technologies, scalable production capabilities, and strategic partnerships.

Key industry leaders include Freudenberg Group, which leverages its extensive expertise in nonwovens to produce nanofiber-based filtration media and technical textiles. Elmarco stands out as a pioneer in industrial-scale electrospinning equipment, enabling both in-house production and technology licensing to textile manufacturers worldwide. Nanofiberlabs and Fibrothelium are notable for their focus on biomedical and high-performance textile applications, often collaborating with research institutions to accelerate innovation.

Asian players, particularly from Japan, South Korea, and China, are increasingly prominent. Toray Industries and Asahi Kasei have integrated electrospun nanofibers into their advanced textile portfolios, targeting both domestic and international markets. Chinese firms such as Suzhou Nanotechnology are rapidly scaling up production, benefiting from strong government support and a robust local supply chain.

Startups and university spin-offs are also shaping the competitive landscape by introducing novel materials (e.g., biodegradable or bioactive nanofibers) and agile manufacturing approaches. Companies like Spin Technologies and Nano and More are gaining traction through niche applications and custom solutions for clients in healthcare and environmental sectors.

Strategic collaborations, mergers, and acquisitions are common as companies seek to expand their technological capabilities and market reach. For example, partnerships between equipment manufacturers and textile producers are accelerating the commercialization of nanofiber-based products. The competitive intensity is expected to increase as more players enter the market and as end-user industries demand higher performance and sustainability from textile materials.

Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

The global textile electrospinning nanofibers market is poised for robust growth between 2025 and 2030, driven by expanding applications in filtration, medical textiles, protective clothing, and energy storage. According to recent projections, the market is expected to register a compound annual growth rate (CAGR) of approximately 18% during this period, reflecting both rising demand and technological advancements in nanofiber production processes. The market’s revenue is forecasted to reach around USD 2.1 billion by 2030, up from an estimated USD 900 million in 2025, indicating a significant expansion in both value and volume terms MarketsandMarkets.

Volume-wise, the production of electrospun nanofibers is anticipated to surpass 18,000 metric tons by 2030, compared to approximately 7,500 metric tons in 2025. This surge is attributed to the scaling up of manufacturing capacities and the adoption of automated, high-throughput electrospinning technologies. The Asia-Pacific region, particularly China, South Korea, and Japan, is expected to dominate both revenue and volume growth, owing to strong investments in research and development, as well as the presence of major textile and filtration product manufacturers Grand View Research.

- Filtration Segment: The filtration application is projected to account for over 35% of total market revenue by 2030, as nanofiber-based filters gain traction in air and liquid filtration systems for industrial, healthcare, and consumer uses.

- Medical Textiles: The medical sector is forecasted to witness the fastest CAGR, exceeding 20%, driven by the adoption of nanofiber scaffolds in wound care, drug delivery, and tissue engineering.

- Protective Clothing: Demand for lightweight, breathable, and high-performance protective textiles is expected to fuel steady growth, particularly in defense and industrial safety applications.

Key market players are intensifying their focus on product innovation and strategic partnerships to capture emerging opportunities. The integration of sustainable and biodegradable polymers in electrospinning processes is also anticipated to open new avenues for market expansion, aligning with global sustainability trends Fortune Business Insights.

Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

The global textile electrospinning nanofibers market is witnessing dynamic growth, with regional trends shaped by technological advancements, end-user demand, and regulatory frameworks. In 2025, North America, Europe, Asia-Pacific, and the Rest of the World (RoW) each present distinct market characteristics and growth drivers.

North America remains a leading region, driven by robust R&D investments and the presence of key industry players. The United States, in particular, benefits from strong collaborations between academic institutions and commercial enterprises, fostering innovation in nanofiber applications for filtration, medical textiles, and smart fabrics. The region’s regulatory environment, emphasizing product safety and performance, further accelerates adoption. According to Grand View Research, North America’s share is bolstered by early adoption in healthcare and defense sectors.

Europe is characterized by a strong focus on sustainability and advanced manufacturing. Countries such as Germany, the UK, and France are investing in eco-friendly nanofiber production processes and integrating nanofibers into high-performance textiles for automotive, filtration, and protective clothing. The European Union’s stringent environmental regulations and funding for nanotechnology research are key growth enablers. MarketsandMarkets highlights Europe’s leadership in green nanofiber technologies and its expanding role in the global value chain.

- Asia-Pacific is the fastest-growing region, propelled by rapid industrialization, expanding textile manufacturing bases, and increasing investments in nanotechnology. China, Japan, and South Korea are at the forefront, leveraging cost-effective production and government support for advanced materials. The region’s large consumer base and growing demand for high-performance textiles in filtration, healthcare, and apparel drive market expansion. Fortune Business Insights notes that Asia-Pacific’s market is expected to outpace other regions in both volume and value by 2025.

- Rest of the World (RoW) includes Latin America, the Middle East, and Africa, where market penetration is emerging but remains limited by infrastructure and investment constraints. However, increasing awareness of nanofiber benefits and gradual adoption in niche applications—such as water filtration and medical textiles—are expected to create new opportunities, particularly in urbanizing regions.

Overall, regional dynamics in 2025 reflect a blend of innovation, regulatory influence, and market readiness, with Asia-Pacific poised for the most significant growth in textile electrospinning nanofibers.

Future Outlook: Emerging Applications and Investment Opportunities

The future outlook for textile electrospinning nanofibers in 2025 is marked by rapid expansion into emerging applications and a surge in investment opportunities. As the technology matures, its unique ability to produce ultra-fine, highly tunable fibers is unlocking new markets beyond traditional textiles, particularly in high-value sectors such as healthcare, filtration, energy, and smart wearables.

In healthcare, electrospun nanofibers are increasingly being adopted for advanced wound dressings, drug delivery systems, and tissue engineering scaffolds. Their high surface area and porosity enable superior cell adhesion and controlled drug release, making them attractive for next-generation medical devices. According to Grand View Research, the medical segment is expected to be one of the fastest-growing end-use areas, driven by ongoing R&D and regulatory approvals.

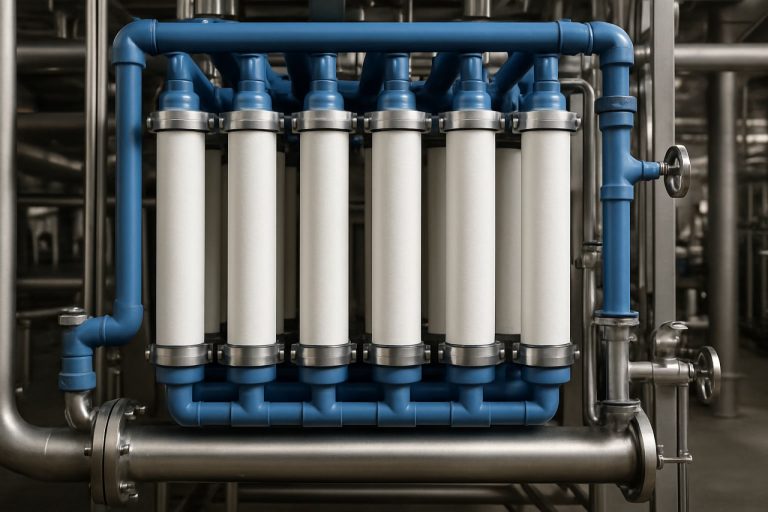

Filtration is another sector witnessing robust growth. Electrospun nanofibers offer exceptional filtration efficiency for air and liquid applications, including industrial air filters, water purification membranes, and personal protective equipment. The COVID-19 pandemic accelerated demand for high-performance filtration materials, a trend that is expected to persist as industries and governments prioritize air quality and public health. MarketsandMarkets projects that filtration will remain a dominant application, with significant investments in scaling up production capacity.

Energy storage and smart textiles represent promising frontiers. Nanofiber-based separators and electrodes are being developed for lithium-ion batteries and supercapacitors, offering improved performance and safety. Meanwhile, the integration of electrospun nanofibers with sensors and conductive materials is enabling the creation of smart fabrics for sports, military, and healthcare monitoring. Companies such as Freudenberg Group and Auburn University are actively investing in R&D partnerships to commercialize these innovations.

- Investment Opportunities: Venture capital and corporate investments are flowing into startups and established players focused on scaling electrospinning technology, automating production, and developing proprietary nanofiber formulations. Strategic collaborations between material science firms, textile manufacturers, and end-user industries are expected to accelerate commercialization.

- Geographic Hotspots: Asia-Pacific, particularly China, Japan, and South Korea, is emerging as a key hub for both production and application development, supported by government funding and a strong manufacturing base.

Overall, 2025 is poised to be a pivotal year for textile electrospinning nanofibers, with expanding applications and robust investment activity driving the market toward mainstream adoption and technological breakthroughs.

Challenges, Risks, and Strategic Opportunities

The textile electrospinning nanofibers market in 2025 faces a complex landscape of challenges, risks, and strategic opportunities as it seeks to transition from niche applications to broader commercial adoption. One of the primary challenges is the scalability of electrospinning processes. While laboratory-scale production of nanofibers is well-established, scaling up to industrial volumes without compromising fiber uniformity, mechanical properties, and cost-effectiveness remains a significant hurdle. High production costs, driven by the need for precise environmental controls and specialized equipment, continue to limit widespread adoption in cost-sensitive textile sectors (Grand View Research).

Material selection and compatibility also pose risks. The range of polymers suitable for electrospinning is expanding, but not all materials exhibit the necessary spinnability or end-use performance, particularly for demanding applications such as protective clothing or medical textiles. Additionally, the use of certain solvents in electrospinning raises environmental and regulatory concerns, especially in regions with stringent chemical management policies (MarketsandMarkets).

Market risks are compounded by the need for standardization and quality assurance. The lack of universally accepted standards for nanofiber properties and performance can hinder customer confidence and slow market penetration. Intellectual property (IP) issues, including patent thickets and licensing complexities, further complicate the competitive landscape, potentially deterring new entrants and stifling innovation (Frost & Sullivan).

Despite these challenges, strategic opportunities abound. The growing demand for high-performance, functional textiles—such as filtration media, smart fabrics, and biomedical materials—offers lucrative avenues for nanofiber applications. Partnerships between research institutions and industry players are accelerating the development of novel nanofiber composites and hybrid materials, expanding the addressable market. Furthermore, advances in green electrospinning techniques, such as solvent-free and aqueous-based processes, are poised to mitigate environmental risks and align with global sustainability trends (IDTechEx).

- Scalability and cost reduction remain top priorities for market expansion.

- Material innovation and eco-friendly processes are key to regulatory compliance and differentiation.

- Strategic collaborations and IP management will shape competitive dynamics and unlock new applications.

Sources & References

- Grand View Research

- Elmarco

- Nanofiberlabs

- Freudenberg Group

- TechnicalTextile.net

- MarketsandMarkets

- Elsevier

- Fibrothelium

- Asahi Kasei

- Nano and More

- Fortune Business Insights

- Auburn University

- Frost & Sullivan

- IDTechEx