Electrolyte Recycling Technologies Market Report 2025: In-Depth Analysis of Growth Drivers, Innovations, and Global Opportunities. Explore Market Size, Key Players, and Forecasts Shaping the Industry’s Future.

- Executive Summary and Market Overview

- Key Technology Trends in Electrolyte Recycling

- Competitive Landscape and Leading Players

- Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

- Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Challenges and Opportunities in Electrolyte Recycling

- Future Outlook: Strategic Recommendations and Emerging Opportunities

- Sources & References

Executive Summary and Market Overview

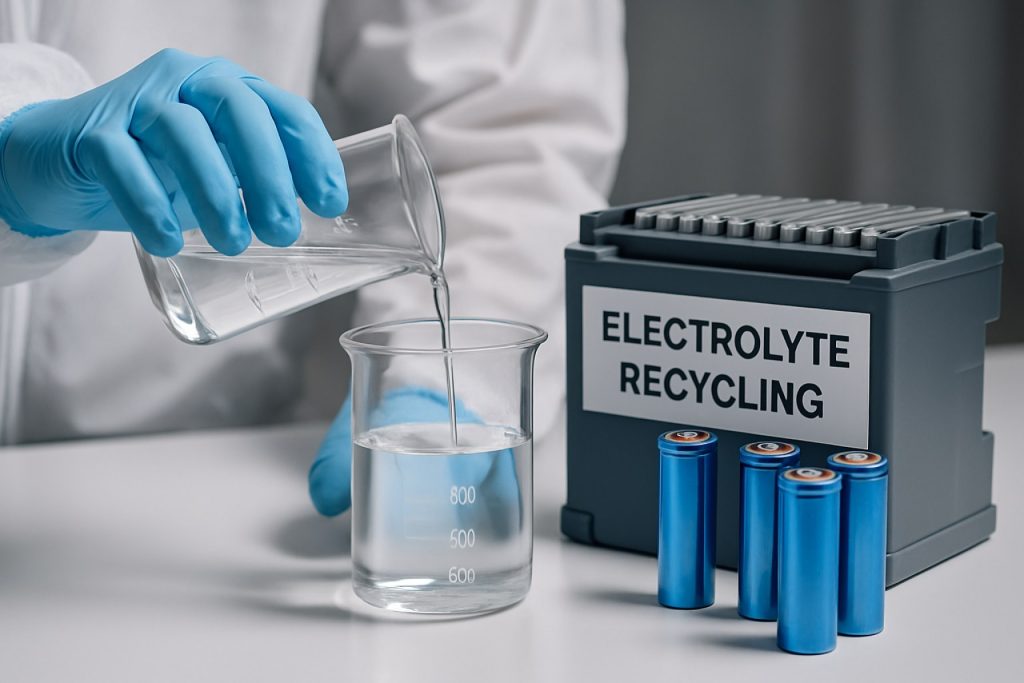

Electrolyte recycling technologies represent a rapidly evolving segment within the broader battery recycling industry, driven by the surging demand for lithium-ion batteries in electric vehicles (EVs), consumer electronics, and grid storage. Electrolytes, typically composed of lithium salts dissolved in organic solvents, are critical for battery performance but pose significant environmental and safety challenges at end-of-life. As global battery production is projected to exceed 3 TWh by 2025, the volume of spent electrolytes requiring sustainable management is set to rise sharply, intensifying the need for advanced recycling solutions International Energy Agency.

The market for electrolyte recycling technologies is characterized by a mix of established players and innovative startups, with significant R&D investments targeting the recovery of high-value materials such as lithium hexafluorophosphate (LiPF6), solvents (e.g., ethylene carbonate, dimethyl carbonate), and emerging solid-state electrolyte components. Key technology approaches include solvent extraction, distillation, membrane separation, and advanced chemical processes designed to minimize hazardous byproducts and maximize material purity. Companies such as Umicore and Redwood Materials are actively developing proprietary processes to recover and purify electrolyte constituents, aiming to close the loop in battery manufacturing and reduce reliance on virgin resources.

- Market Drivers: Stringent environmental regulations in the EU, US, and China are mandating higher recycling rates and safer disposal of battery waste, directly supporting the adoption of electrolyte recycling technologies. Additionally, supply chain disruptions and price volatility for lithium and other critical minerals are incentivizing manufacturers to secure secondary sources through recycling European Environment Agency.

- Challenges: Technical barriers remain, including the safe handling of flammable and toxic electrolyte components, the economic viability of recovery processes, and the integration of recycling streams into existing battery value chains. The lack of standardized battery designs further complicates efficient electrolyte extraction and purification.

- Outlook: By 2025, the global market for electrolyte recycling technologies is expected to witness double-digit annual growth, with Asia-Pacific leading in capacity expansion and technology deployment. Strategic partnerships between battery manufacturers, recyclers, and chemical companies are anticipated to accelerate commercialization and scale-up efforts Benchmark Mineral Intelligence.

In summary, electrolyte recycling technologies are poised to become a cornerstone of the sustainable battery ecosystem by 2025, offering both environmental benefits and economic opportunities as the world transitions to electrified mobility and renewable energy storage.

Key Technology Trends in Electrolyte Recycling

Electrolyte recycling technologies are rapidly evolving in response to the surging demand for lithium-ion batteries and the imperative to reduce environmental impact from battery waste. As of 2025, several key technology trends are shaping the landscape of electrolyte recycling, focusing on both economic viability and environmental sustainability.

One of the most significant advancements is the development of solvent-based extraction methods. These processes utilize selective solvents to recover valuable electrolyte components, such as lithium hexafluorophosphate (LiPF6), from spent batteries. Recent innovations have improved the selectivity and efficiency of these solvents, enabling higher recovery rates and purer end products. Companies like Umicore and Brunp Recycling are investing in proprietary solvent extraction technologies to scale up commercial operations.

Another trend is the integration of membrane separation technologies. Advanced membranes can selectively separate and purify electrolyte salts and solvents, reducing the need for energy-intensive distillation. Research institutions and industry players, such as BASF, are piloting membrane-based systems that promise lower operational costs and reduced chemical usage.

Thermal and supercritical fluid extraction methods are also gaining traction. Supercritical CO2 extraction, for example, offers a non-toxic and efficient route to recover organic solvents from used electrolytes. This technology is being explored by several startups and academic groups, with pilot projects demonstrating its potential for scalability and environmental compatibility.

Direct regeneration of electrolytes is an emerging approach, where spent electrolytes are purified and reconditioned for reuse without full decomposition into raw materials. This method, championed by companies like Redwood Materials, can significantly reduce processing steps and costs, aligning with circular economy principles.

Finally, digitalization and process automation are enhancing the efficiency and traceability of electrolyte recycling operations. Real-time monitoring, AI-driven process optimization, and blockchain-based tracking systems are being implemented to ensure quality control and regulatory compliance across the recycling value chain.

Collectively, these technology trends are driving the electrolyte recycling sector toward higher recovery rates, lower environmental impact, and improved economic feasibility, positioning it as a critical component of the sustainable battery supply chain in 2025 and beyond.

Competitive Landscape and Leading Players

The competitive landscape for electrolyte recycling technologies in 2025 is characterized by rapid innovation, strategic partnerships, and increasing investments from both established industry leaders and emerging startups. As the global demand for lithium-ion batteries surges—driven by electric vehicles (EVs), energy storage systems, and portable electronics—efficient recycling of battery electrolytes has become a critical focus for sustainability and supply chain resilience.

Key players in this sector are leveraging proprietary chemical processes, solvent extraction, and advanced filtration techniques to recover valuable electrolyte components such as lithium hexafluorophosphate (LiPF6), organic solvents, and additives. The market is witnessing a shift from traditional pyrometallurgical and hydrometallurgical recycling methods toward more selective and environmentally friendly approaches tailored specifically for electrolyte recovery.

- Umicore has expanded its battery recycling capabilities to include electrolyte recovery, integrating solvent extraction and purification technologies at its European facilities. The company’s partnerships with automotive OEMs and battery manufacturers position it as a leader in closed-loop battery material supply chains.

- Redwood Materials is pioneering scalable electrolyte recycling in the United States, focusing on recovering and purifying lithium, cobalt, nickel, and electrolyte solvents. Their vertically integrated approach and collaborations with EV manufacturers have accelerated the commercialization of recycled electrolyte products.

- SungEel HiTech in South Korea has developed proprietary processes for extracting and reusing electrolyte components from spent batteries, with a focus on high recovery rates and minimal environmental impact. The company’s expansion into Europe and North America underscores its global ambitions.

- Brunp Recycling, a subsidiary of CATL, is investing heavily in R&D for advanced electrolyte separation and purification, aiming to support CATL’s battery manufacturing with sustainable, recycled materials.

- Startups such as CYCLE and ACE Green Recycling are introducing novel, low-energy processes for electrolyte recovery, attracting venture capital and forming alliances with battery producers to pilot their technologies at scale.

The competitive landscape is further shaped by regulatory pressures in the EU, US, and Asia, which are mandating higher recycling rates and extended producer responsibility. As a result, leading players are not only competing on technology and cost, but also on their ability to deliver traceable, high-purity recycled electrolytes that meet stringent industry standards. The next few years are expected to see increased consolidation, technology licensing, and cross-border collaborations as the market matures and scales.

Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

The global market for electrolyte recycling technologies is poised for robust growth between 2025 and 2030, driven by the accelerating adoption of electric vehicles (EVs), expanding energy storage systems, and tightening environmental regulations. According to projections by IDTechEx, the battery recycling sector—including electrolyte recovery—is expected to achieve a compound annual growth rate (CAGR) of approximately 21% during this period. This surge is underpinned by the increasing volume of end-of-life lithium-ion batteries, which are forecast to reach over 2 million tons annually by 2030.

Revenue from electrolyte recycling technologies is anticipated to surpass $2.5 billion by 2030, up from an estimated $700 million in 2025. This growth is attributed to both technological advancements in solvent extraction, membrane separation, and direct regeneration processes, as well as the scaling up of commercial recycling facilities in key markets such as China, Europe, and North America. Benchmark Mineral Intelligence reports that China currently leads in installed recycling capacity, but significant investments in the EU and US are expected to narrow this gap by 2030.

In terms of volume, the amount of electrolyte material recovered is projected to grow from approximately 30,000 metric tons in 2025 to over 150,000 metric tons by 2030. This fivefold increase reflects both the rising number of batteries reaching end-of-life and improved recovery rates enabled by next-generation recycling technologies. Companies such as Umicore, Redwood Materials, and Northvolt are at the forefront of scaling up operations and innovating processes to maximize electrolyte recovery and purity.

- CAGR (2025–2030): ~21%

- Revenue (2030): $2.5 billion+

- Volume (2030): 150,000+ metric tons of electrolyte recovered

Overall, the electrolyte recycling technologies market is set for dynamic expansion, with policy support, technological innovation, and the circular economy imperative acting as primary growth drivers through 2030.

Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

The global market for electrolyte recycling technologies is experiencing significant regional variation, driven by regulatory frameworks, industrial maturity, and the pace of electric vehicle (EV) adoption. In 2025, North America, Europe, Asia-Pacific, and the Rest of the World (RoW) each present distinct opportunities and challenges for the deployment and scaling of electrolyte recycling solutions.

- North America: The United States and Canada are witnessing rapid growth in battery manufacturing and EV adoption, spurred by government incentives and sustainability mandates. The U.S. Environmental Protection Agency and the U.S. Department of Energy have launched initiatives to support battery recycling infrastructure, including electrolyte recovery. Companies such as Redwood Materials and Li-Cycle are expanding their operations, leveraging hydrometallurgical and solvent-based processes to recover and purify electrolytes from spent lithium-ion batteries. The region’s focus is on closed-loop recycling to reduce reliance on imported raw materials and enhance supply chain resilience.

- Europe: The European Union’s stringent regulations, such as the proposed Battery Regulation, are accelerating the adoption of advanced recycling technologies, including electrolyte recovery. The European Commission is funding research and pilot projects to improve the efficiency and environmental impact of electrolyte recycling. Companies like Umicore and Northvolt are investing in integrated recycling facilities that target not only metals but also organic solvents and lithium salts from electrolytes. The region’s circular economy agenda is a key driver, with a focus on reducing hazardous waste and maximizing resource recovery.

- Asia-Pacific: As the world’s largest battery manufacturing hub, Asia-Pacific—led by China, Japan, and South Korea—dominates the electrolyte recycling landscape. The Ministry of Industry and Information Technology of the People’s Republic of China has set ambitious targets for battery recycling rates, prompting major players like CATL and GEM Co., Ltd. to develop proprietary electrolyte recovery technologies. The region benefits from economies of scale and a mature supply chain, but faces challenges related to environmental compliance and technology standardization.

- Rest of World: In regions such as Latin America, the Middle East, and Africa, electrolyte recycling is in its nascent stages. However, growing investments in battery manufacturing and resource extraction are expected to drive future demand for recycling technologies. International partnerships and technology transfers, often supported by organizations like the World Bank, are crucial for capacity building and market development in these areas.

Overall, 2025 is set to be a pivotal year for the global electrolyte recycling market, with regional dynamics shaped by policy, industrial capability, and the evolving needs of the battery value chain.

Challenges and Opportunities in Electrolyte Recycling

Electrolyte recycling technologies are at the forefront of addressing the environmental and economic challenges posed by the rapid growth of lithium-ion battery usage, particularly in electric vehicles and energy storage systems. As the volume of spent batteries increases, the need for efficient, scalable, and cost-effective electrolyte recycling solutions becomes more urgent. The main challenges in this sector stem from the complex chemical composition of electrolytes, which typically include organic solvents, lithium salts (such as LiPF6), and various additives. These components are often volatile, flammable, and toxic, complicating their safe extraction and purification.

Current technologies for electrolyte recycling can be broadly categorized into physical separation, solvent extraction, and advanced chemical processes. Physical separation methods, such as vacuum distillation, are relatively simple but often result in low recovery rates and purity levels. Solvent extraction techniques, while more effective, require careful management of secondary waste streams and can be energy-intensive. Advanced chemical processes, including supercritical fluid extraction and membrane separation, show promise for higher recovery rates and selectivity but are still in the pilot or early commercialization stages due to high capital and operational costs.

One of the key opportunities lies in the development of closed-loop recycling systems, where recovered electrolytes are directly reused in new battery manufacturing. Companies such as Umicore and Redwood Materials are investing in research to improve the purity of recovered solvents and lithium salts, aiming to meet the stringent quality requirements of battery producers. Additionally, the integration of digital tracking and process automation is enhancing the efficiency and traceability of recycling operations, as highlighted in recent industry reports by Benchmark Mineral Intelligence.

Regulatory support and evolving producer responsibility frameworks in regions like the European Union and China are also driving innovation in electrolyte recycling technologies. The EU’s Battery Regulation, for example, sets ambitious targets for material recovery and reuse, incentivizing investment in advanced recycling infrastructure (European Commission). However, the sector still faces hurdles related to the safe handling of hazardous materials, the variability of spent battery chemistries, and the need for standardized processes across the supply chain.

In summary, while significant technical and economic challenges remain, ongoing advancements in electrolyte recycling technologies present substantial opportunities for reducing environmental impact, securing critical raw materials, and supporting the sustainable growth of the battery industry.

Future Outlook: Strategic Recommendations and Emerging Opportunities

The future outlook for electrolyte recycling technologies in 2025 is shaped by accelerating demand for lithium-ion batteries, tightening environmental regulations, and the strategic imperative to secure critical mineral supply chains. As the global electric vehicle (EV) market and stationary energy storage sectors expand, the volume of spent batteries is projected to surge, intensifying the need for efficient and sustainable recycling solutions. Electrolyte recycling, which focuses on recovering valuable solvents and salts from used batteries, is emerging as a key area of innovation and investment.

Strategically, industry stakeholders are advised to prioritize the development and scaling of advanced separation and purification processes. Technologies such as solvent extraction, membrane filtration, and supercritical fluid extraction are gaining traction for their ability to selectively recover high-purity electrolyte components. Companies investing in these technologies can position themselves as critical partners in the battery circular economy, reducing reliance on virgin materials and mitigating supply chain risks. For example, Umicore and Redwood Materials are actively expanding their recycling capabilities to include electrolyte recovery, aiming to close the loop on battery materials.

Emerging opportunities also lie in the integration of recycling operations with battery manufacturing. Co-locating recycling and production facilities can lower logistics costs, reduce carbon footprints, and enable real-time quality control of recovered materials. Strategic partnerships between battery manufacturers, automakers, and recycling technology providers are expected to proliferate, as evidenced by recent collaborations such as BASF’s alliances with battery OEMs to develop closed-loop recycling systems.

- Regulatory incentives: The European Union’s Battery Regulation, effective from 2025, mandates higher recycling efficiencies and material recovery rates, creating a favorable policy environment for electrolyte recycling investments (European Commission).

- Technology commercialization: Startups and established players are racing to commercialize scalable electrolyte recovery processes, with pilot projects transitioning to full-scale operations in North America, Europe, and Asia (Benchmark Mineral Intelligence).

- New business models: Service-based models, such as “recycling-as-a-service,” are emerging, offering battery producers and EV manufacturers turnkey solutions for end-of-life management and material recovery.

In summary, 2025 will be a pivotal year for electrolyte recycling technologies, with strategic investments, regulatory support, and collaborative business models driving the sector toward commercial maturity and broader adoption.

Sources & References

- International Energy Agency

- Umicore

- Redwood Materials

- European Environment Agency

- Benchmark Mineral Intelligence

- Brunp Recycling

- BASF

- CATL

- CYCLE

- IDTechEx

- Northvolt

- Li-Cycle

- European Commission

- GEM Co., Ltd.

- World Bank